For detailed information, other images and documents, please select individual articles from the following table.

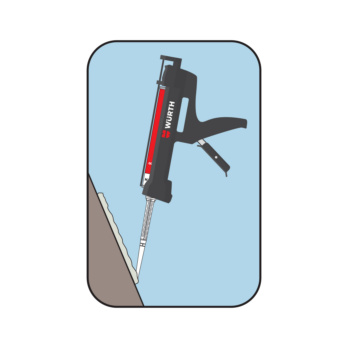

Injectable mortar, WIT-VIZ Express

Fast curing composite mortar for the injection systems W-VIZ (concrete) and W-VIZ dynamic (fatigue-related influences)

Register now and access more than 150,000 products

Variants

Register now and access more than 150,000 products

- Fast curing

- Cartridge can continue to be used until the best before date, by changing the mixer nozzle or resealing it with the end cap

- Two-part reactive resin mortar, styrene-free vinylester

- Individual fixing point in cracked and uncracked concrete: Anchor rod W-VIZ-A, internally threaded sleeve W-VIZ-IG

- Earthquake C1 and C2 (W-VIZ-A M10 to M24)

- Individual fixing point, dynamic: Anchor rod W-VIZ-A dyn. and W-VIZ-AV dyn.

- European Technical Assessment ETA-04/0095: Individual fixing point + cracked and uncracked concrete (anchor rod W-VIZ-A, female thread anchor W-VIZ-IG)

- European Technical Assessment ETA-18/0979: Retroactively installed fasteners in concrete under fatigue cyclic loading (anchor rod W-VIZ-A/S dynamic, W-VIZ-AV/S dynamic)

Fence systems

Fence systems

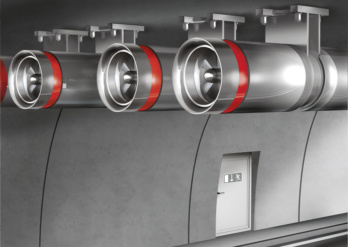

Tunnel ventilation (fatigue-related influences)

Tunnel ventilation (fatigue-related influences)

Post support bracket

Post support bracket

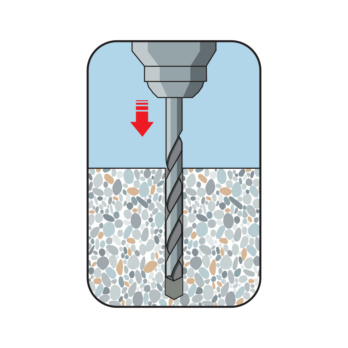

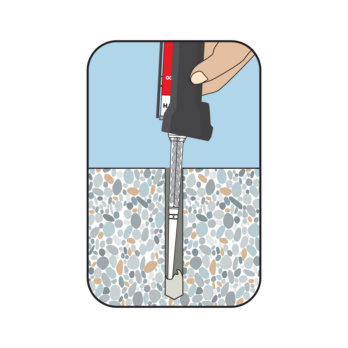

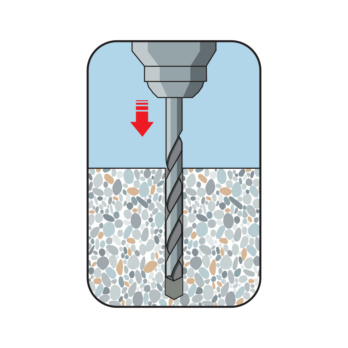

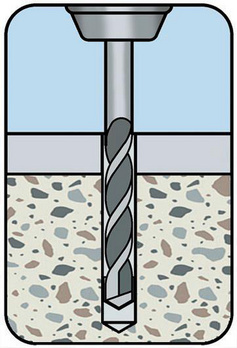

Drill the hole

Drill the hole using a Würth dust extraction drill bit. The drill hole does not require cleaning

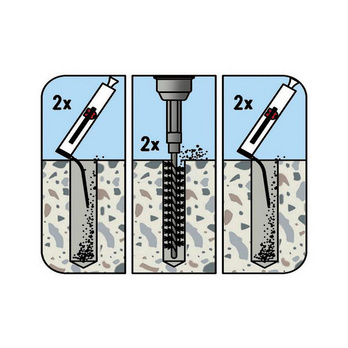

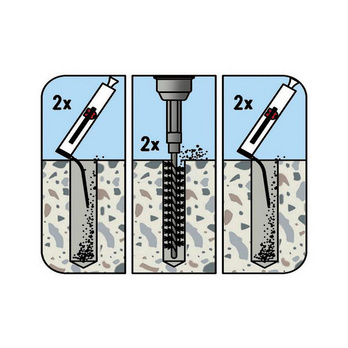

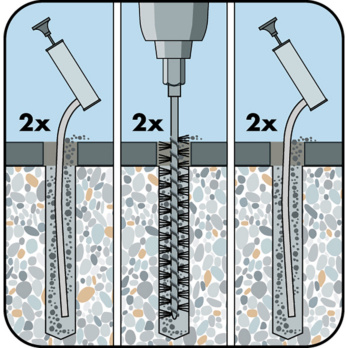

Clean the drill hole

2x blow out, 2x mechanical brush out, 2x blow out

Blow out with compressed air from M20 drilled hole

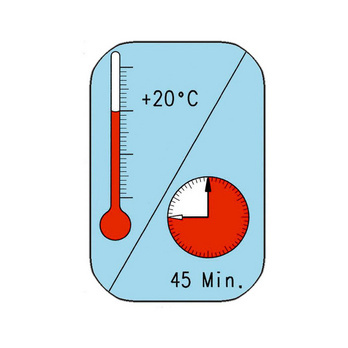

Measure temperature

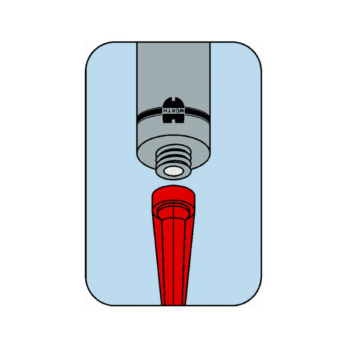

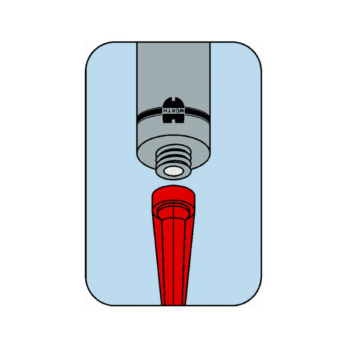

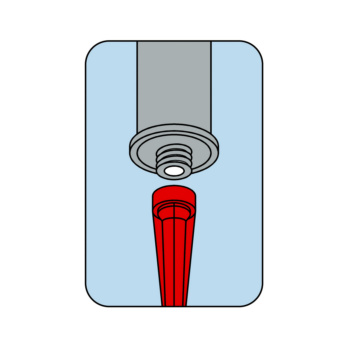

Screw mixer onto cartridge

Discard the first section of mortar (until the mortar is uniformly coloured - approx. 10 cm)

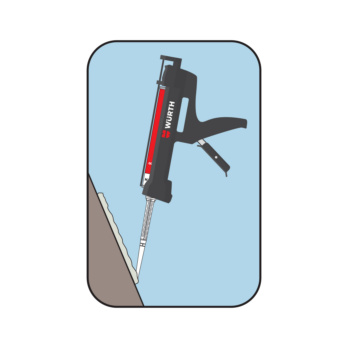

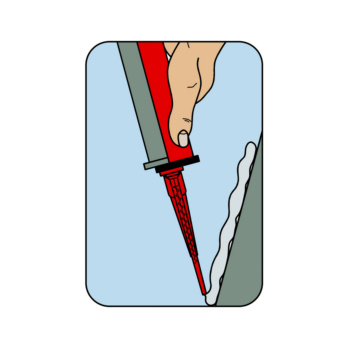

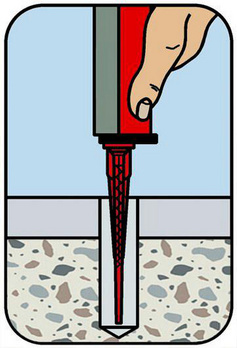

Fill injection mortar starting from base of drill hole

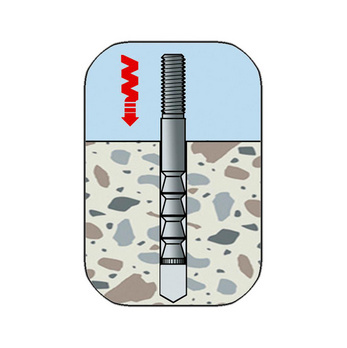

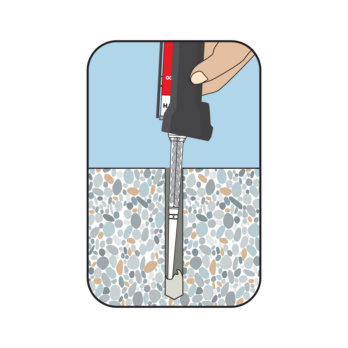

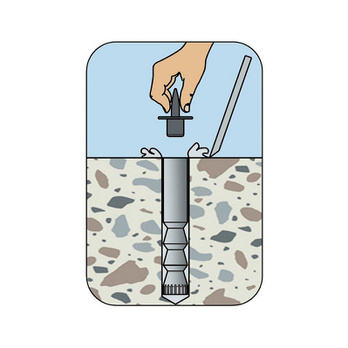

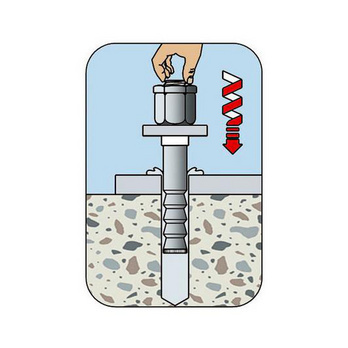

Press in anchor rod up to drill hole base while turning slightly

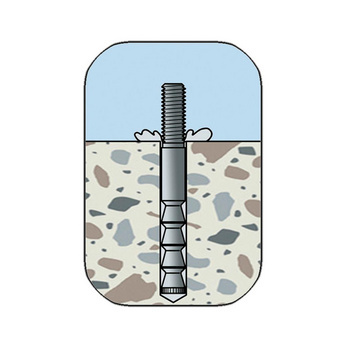

Visual check of mortar filling quantity, setting depth marking

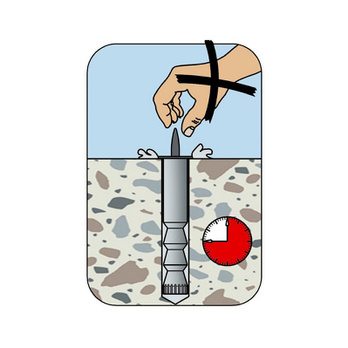

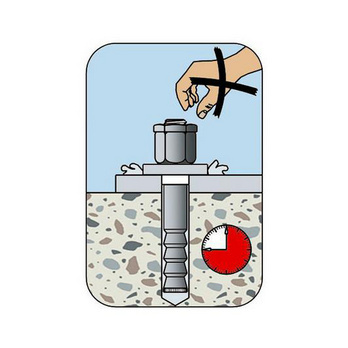

Observe the injection mortar curing time

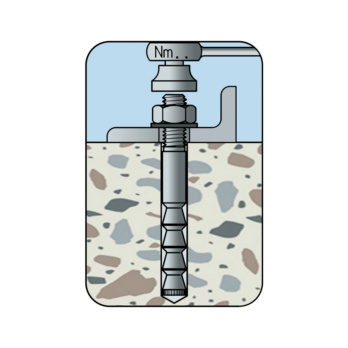

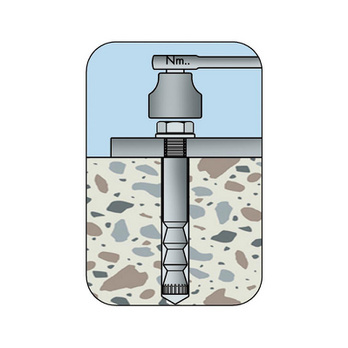

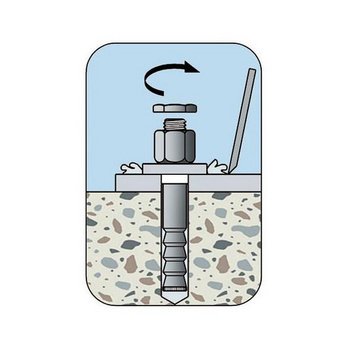

Install component, apply installation torque

Drill the hole

Drill the hole using a Würth dust extraction drill bit. The drill hole does not require cleaning

Clean the drill hole

2x blow out, 2x mechanical brush out, 2x blow out

Blow out with compressed air from M20 drilled hole

Measure temperature

Screw mixer onto cartridge

Discard the first section of mortar (until the mortar is uniformly coloured - approx. 10 cm)

Fill injection mortar starting from base of drill hole

Push in female-thread anchor while turning slightly

Carry out visual check and comply with composite mortar hardening time

Remove extruded mortar and protective cap

Install component; maximum torque may not be exceeded

Create the drill hole

Clean drill hole (blow out 2 x, brush out mechanically 2 x, blow out 2 x), with M20 and larger, blow out with pneumatic air (pneumatic air nozzle)

Screw mixer onto cartridge

Before use, press out approx. 10 cm cord. Do not use this initial mortar!

Fill injection mortar starting from base of drill hole

Press in anchor rod up to drill hole base while turning slightly

Observe the injection mortar curing time

After the hardening time, remove extruded mortar

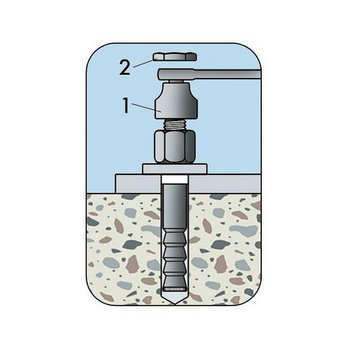

1. Apply installation torque

2. Screw on the locking nut, then tighten with a wrench ¼ to ½ a turn

- Anchor rod W-VIZ-A: Railings, metal structures and profiles, brackets, supports, steps, etc.

- Female thread anchor W-VIZ-IG: Railings, metal structures and steps, etc.

- Anchor rod W-VIZ-A dynamic: Slewing cranes, crane runways, ventilation fans, welding robots, conveyors, street signs, etc.

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!