Plastic anchor with pan head screw ZEBRA Shark W-ZX®

Plastic anchor Shark W-ZX, pan head screw AW

DWL-(W-ZX)-PANHD-AW30-(A2K)-8X46/60

ZEBRA

Register now and access more than 150,000 products

Variable attachment heights

(Penetration of the screw tip >= 5 mm, threaded part of screw must be in anchor)

Plug screw ASSY-D without drill tip, counter thread or ring thread, galvanised steel

(Particle board screws, with e.g. a drill tip, hollow out the plastic anchor. The decreased amount of plastic reduces the expansion force and, consequently, the load-bearing capacity)

- Low insertion torque and high fixed torque

- Guaranteed knotting in all cavities and expansion in all solid materials (without approval)

- Fold-down anchor collar: Anchor can be used for cotter-pin (with approval) and push-through installation (without approval)

- The anti-rotation device or twist lock prevents turning in the drill hole.

- Anchorage via friction locking between anchor sleeve and anchoring base

- The wall plug body is made of high-quality polyamide.

W-ZX 6, 8, 10, 12, 14

European Technical Approval ETA-12/0042 Multiple attachment of non-load-bearing systems in concrete

W-ZX 10

European Technical Approval ETA-12/0042 multiple attachment of non-load-bearing systems in masonry, aerated concrete, hollow-core prestressed concrete ceilings

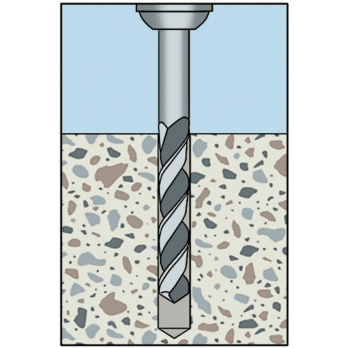

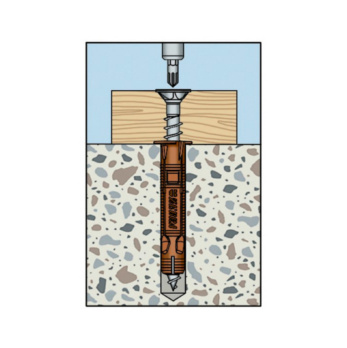

Create the drill hole

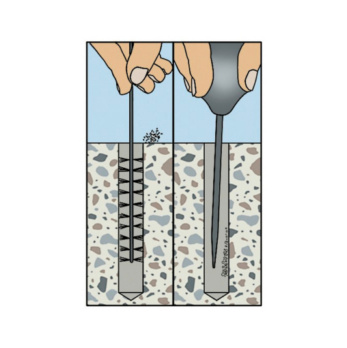

Clean the drill hole

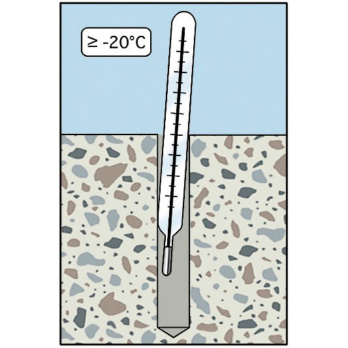

Dowel sleeve temperature >= 0°C.

Temperature of anchoring base ≥ -20°C

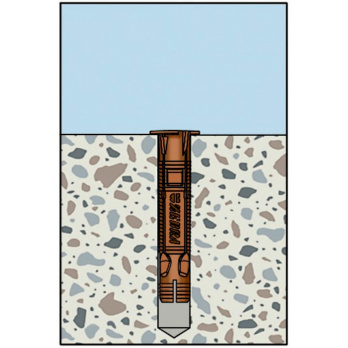

Install anchor

Screw in the screw flush through the attachment part

Datasheets(X)

The anchor has European Technical Approval for the multiple attachment of non-load-bearing systems

e.g. ceiling substructures (made from wood or steel), wooden laths, metal rails, suspended ceilings, profiles, wardrobes, wall shelves, lightweight wall cupboards, mirrors, lamps, cable ducts, electrical switches, motion detectors etc.

W-ZX has approval for anchoring in the following bases:

- Cracked and non-cracked standard concrete > C12/15 (ZEBRA Shark WZ-X® 6, 8, 10, 12, 14)

- Masonry (ZEBRA Shark W-ZX® 10)

- Solid brick, solid sand-lime brick, vertically perforated brick, hollow sand-lime brick, solid bricks and solid blocks made of lightweight concrete and standard concrete (ZEBRA Shark W-ZX® 10)

- Aerated concrete, hollow-core prestressed concrete ceilings (ZEBRA Shark W-ZX® 10)

Anchor diameter | 8 mm |

Anchor length (l) | 46 mm |

Screw length (ls) | 60 mm |

Min. height of the fixture (t fix) | 1 mm |

Max. attachment height (t fix) | 10 mm |

Embedding depth (h nom) | 45 mm |

Nominal drill-bit diameter (d 0) | 8 mm |

Drill hole depth (h 1) - condition | l(s) + 5 mm - t(fix) |

Surface of the screw | Zinc plated |

| Performance data: Concrete, anchors in a redundant non-structural system in non-load-bearing systems | |||||||

| Anchor diameter | [mm] | W-ZX 6 | W-ZX 8 | W-ZX 10 | W-ZX 12 | W-ZX 14 | |

| Setting depth of the wall plug body | hnom [mm] | 34 | 45 | 55 | 65 | 75 | |

| Central tensile load1) for single anchors or dowel group | Nperm = C12/15 [kN] | 24°C2)/40°C3) | 0,30 | 0,36 | 0,99 | 1,59 | 1,79 |

| Nperm ≥ C16/20 [kN] | 24°C2)/40°C3) | 0,36 | 0,48 | 1,39 | 1,749 | 2,18 | |

| Shear load1) for single anchors or dowel group | Vperm | [kN] | 1,62 | 2,59 | 4,67 | 6,79 | 8,55 |

| Minimum component thickness | hmin | [mm] | 100 | 100 | 100 | 120 | 120 |

| Minimum axis distance4) | smin [mm] | C12/15 | 110 | 110 | 110 | 210 | 210 |

| ≥ C16/20 | 80 | 80 | 80 | 150 | 150 | ||

| Minimum Edge clearance4) | cmin [mm] | C12/15 | 110 | 110 | 110 | 210 | 210 |

| ≥ C16/20 | 80 | 80 | 80 | 150 | 150 | ||

| Characteristic Edge spacing | ccr,N [mm] | C12/15 | 120 | 110 | 110 | 210 | 210 |

| ≥ C16/20 | 80 | 80 | 80 | 150 | 150 | ||

| 1) The partial safety factors of the resistances regulated in the approval and a partial safety factor of the effects of γF = 1.4 have been taken into account. For the combination of tensile and shear loads, please note ETAG 020 Appendix C 2) Maximum long-term temperature 3) Maximum short-term temperature 4) Permissible load must be reduced | |||||||

| Installation parameters: Concrete + masonry (only ZEBRA® Shark W-ZX 10) | ||||||

| Anchor diameter | [mm] | W-ZX 6 | W-ZX 8 | W-ZX 10 | W-ZX 12 | W-ZX 14 |

| Nominal drill diameter | d0 [mm] | 6 | 8 | 10 | 12 | 14 |

| Drill cutting diameter | dcut ≤ [mm] | 6,4 | 8,45 | 10,45 | 12,45 | 14,45 |

| Drill hole depth | h1 ≥ [mm] | ls + 5 mm - tfix | ||||

| Setting depth of the wall plug body | hnom [mm] | 34 | 45 | 55 | 65 | 75 |

| Through hole in attachment part | df ≤ [mm] | 5,5 | 6,5 | 8,5 | 10,5 | 12,5 |

| Performance data: Masonry 4) (only ZEBRA® Shark W-ZX 10), multiple attachments of non-load-bearing systems (temperature range 20°C2) / 40°C3))For other types of stone, raw densities, minimum pressure strength, edge and axis distances or temperature ranges, please refer to the approval ETA-12/0042 | ||||

| Brick type | Brick format [mm] | Raw density class [kg/dm³] | Minimum compressive strength [N/mm²] | Fperm [kN] 1) 5) (for single anchors or dowel group) W-ZX 10 |

| Anchoring depth | hnom [mm] | 55 | ||

| Brick Mz, EN 771-1, DIN 105 | ≥ NF (≥ 240 x 115 x 71) | ≥ 1.8 | 10 | 0,34 |

| 20 | 0,57 | |||

| 28 | 0,71 | |||

| 36 | 1 | |||

| ≥ NF (≥ 240 x 115 x 71) | ≥ 1.8 | 8 | 0,21 | |

| 12 | 0,34 | |||

| 20 | 0,57 | |||

| Vertically perforated brick HLz, EN 771-1, DIN 105 | ≥ 12DF (≥ 373 x 240 x 238) | ≥ 1.2 | 4 | 0,34 |

| 6 | 0,43 | |||

| 8 | 0,71 | |||

| Solid sand-lime brick KS, EN 771-2, DIN 106 | ≥ NF (≥ 240 x 115 x 71) | ≥ 2.0 | 10 | 0,34 |

| 20 | 0,43 | |||

| 28 | 0,71 | |||

| 1) The partial safety factors of the resistances regulated in the approval and a partial safety factor of the effects of γF = 1.4 have been taken into account. For the combination of tensile and shear loads, please refer to ETAG 020 Appendix C 2) Maximum long-term temperature 3) Maximum short-term temperature 4) For other types of stone, raw densities, minimum pressure strengths or temperature ranges, please refer to the approval ETA-12/0042 5) The stone geometry should be compared with the approval ETA-12/0042 | ||||