Moisture-variable vapour retarder WÜTOP® Thermo Vario SD

Moisture-variable vap retard WÜTOP Thermo Vario SD

VAPRETRDR-(VARIO SD)-W1,5M-L50M

Register now and access more than 150,000 products

WÜTOP Thermo Vario SD is a vapour-permeable, moisture-variable and airtight vapour retarder for the renovation of old buildings, interior finishing and loft conversions. When combined with WÜTOP non-breathable and breathable membranes and EURASOL adhesive tapes, it can be used to create modern airtight and windproof structures.

Safety

Polyester is an extremely weather-resistant material, provides a high degree of protection against UV radiation and is temperature-resistant up to 100 °C.

Technology

Two-layer vapour retarder consisting of moisture-variable polyamide with stabilising polyester fleece.

For universal use

- Roofs, walls and floors

- Renovation of old buildings from the outside (sub and top processes)

- Damp new buildings (with adequate ventilation)

Time and cost savings

- Installation grid for easy and quick installation (10 x 10 cm)

- Very robust and tear-resistant thanks to polyester fleece backing

Our products featuring the EMICODE label are low-emission/low in harmful substances. The EMICODE classification system awards labels to construction products that comply with the very stringent health and environmental requirements of recognised institutes.

DIN EN 13984

EMICODE EC1plus: Very low emissions: The EMICODE classification system distinguishes the environmental and health compatibility of construction products. The lowest-emission products bear the EC1plus mark.

Please refer to the current ZVDH [German Central Association of the Roofing Trade] directives and instructions for laying this product.

Datasheets(X)

Installation instructions for between-rafter insulation

- Fix WÜTOP Thermo Vario SD to the warm side of the heat insulation using a stapler (hammer tacker art. no. 0714854, 0714811 or hand-held stapler art. no. 0714834) and secure with battens.

- The smooth side always faces toward the installer.

- Vertical overlaps must always lie on a rafter.

- Ensure sufficient overlap: Horizontal overlap: at least 10 cm (overlap strip), vertical overlap: approx. 20 cm.

- Airtight bonding with a suitable adhesive tape (art. no. 0992700050) is recommended for all overlaps and stapled points.

- For airtight attachment to masonry, the membrane is bonded using WÜTOP film adhesive (art. no. 0893700100, 0893700110) and secured with a clamping batten, if necessary.

- Take care not to damage the membrane during installation.

- Before the interior cladding (gypsum plasterboard, wood panelling etc.) is attached, check again that the vapour retarder has been correctly installed and remedy if necessary.

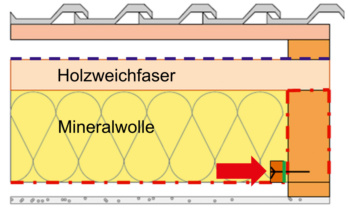

Installation instructions for over-rafter insulation

- WÜTOP Thermo Vario SD is ideal for use as a vapour retarder for over-rafter insulation.

- Installation: Same procedure as for between-rafter insulation.

- Please keep in mind: Exposure to weather for max. 3 months.

Installation instructions for renovation of old buildings

- Sharp objects (e.g. nails) that protrude from the interior cladding into the rafter area must be removed to avoid damaging the vapour retarder.

- WÜTOP Thermo Vario SD is laid over the rafters from the outside with the fleece facing the room interior. Install with the smooth side facing outwards.

- All overlaps and openings must be given an airtight seal using suitable adhesive tape (Eurasol, art. no. 0992700050).

- Recommendations: Secure WÜTOP Thermo Vario SD to the rafters using clamping battens.

- Bond joints at the eaves (eave beams/masonry) using WÜTOP film adhesive (art. no. 08937001). Additional mechanical fixing with clamping battens is recommended.

Coating weight per m² | 100 g |

Length of roll | 50 m |

Roll width | 1.5 m |

Area | 75 m² |

Number of rolls per pallet | 30 PCS |

Material | 0 - not applicable |

Min./max. temperature resistance | -40 to 100 °C |

Thickness | 0.4 mm |

Building material class/conditions | E, d2 - Normally inflammable / in accordance with DIN EN 13501 |

Resistance to penetration of water | W1 |

Resistance to tear propagation (longitudinal) | 59 N |

Resistance to tear propagation (transverse) | 65 N |

Longitudinal tensile force per 50 mm | 180 N |

Transverse tensile force per 50 mm | 140 N |

Colour | White, Transparent |

Min./max. air layer thickness equivalent to water-vapour diffusion /conditions | 0.18-20 m / in accordance with EN ISO 12572 |

Width | 1.5 m |

Sustainability | Pollutants / Emissions |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!