Hexagon nut with clamping piece (all-metal) fine thread ISO 10513, steel, strength class 10, zinc flake, silver (ZFSHL)

ISO 10513 steel 10 silver zinc flake, fine thread

NUT-ISO10513-10-WS18-(ZFSHL)-M12X1,5

Register now and access more than 150,000 products

Zinc-flake coatings are chromium(VI)-free corrosion protection coatings for commercial vehicle construction, construction machines, agricultural vehicles and equipment, and all other fields that have vehicle construction standard corrosion protection requirements.

The corrosion resistance of ZFHSL is as follows:

- Diameter ≥ M6 - 480h*

- Diameter ≥ M10 - 720h*

- * Guideline values: No base metal corrosion at points without thread in salt spray mist testing according to DIN EN ISO 9227 NSS

The designation ZFSHL refers to the following corrosion coating:

- Zinc flake coating, with top coat, silver colour, with lubrication that alters the friction coefficient

- Adjusted friction coefficient range from 0.09–0.14 μ due to top coat with integrated lubricating particles

ISO 10513 replaces DIN 980 with fine thread. There is some limited similarity (thread M18×2, M18×1.5, M20×2, M22×2, M22×1.5, M27×2, M33×2 and M39×3 removed | Nut height changed | Width across flats changed for M10, M12 and M14 to 16, 18 and 21 mm | Standard thread included in ISO 7042 | Strength class 5 removed | ISO 10513 applies to the strength classes 8, 10, 12).

Datasheets(X)

| |

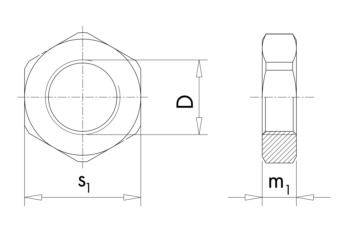

Thread type x nominal diameter x pitch (D) | M12 x 1.5 |

Height (m1) | 13.30 mm |

External drive (s1) | WS18 |

Standards | ISO 10513 |

Material | Steel |

Property class | 10 |

Surface | Flake zinc silver |

RoHS-compliant | Yes |

Corrosion protection period | 720 h |

Locking device operating principle | Single part clamping nut metal |

Locking function | Locking against loosening by clamping |