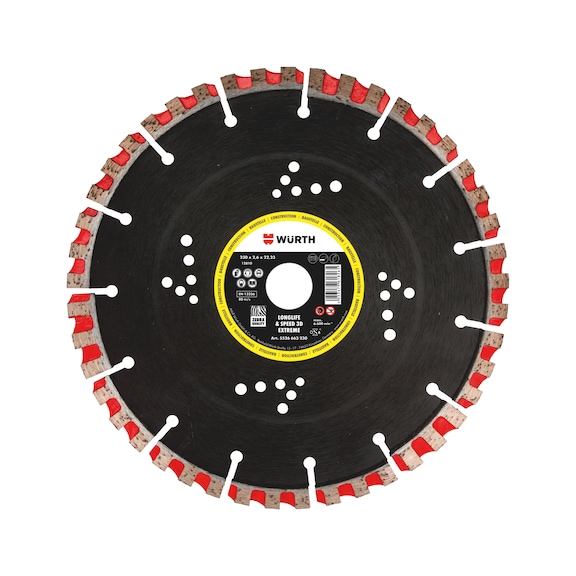

Diamond cutting disc Longlife & Speed 3D Extreme

Diamond cutting disc LS Bau 3D-Extreme ang. gr.

CUTDISC-DIA-LS-3D-EX-CNST-BR22,23-D230MM

ZEBRA

Register now and access more than 150,000 products

3D technology

Special arrangement of the diamonds for outstanding cutting properties

Protection against undercut — especially when working with particularly abrasive materials

Thanks to 3 special protective segments with a height of 15 mm.

3x more cutting edges when compared with similar cutting discs

Thanks to a new segment shape (short tooth technology).

Optimised cooling

Special cooling openings with an "arrow arrangement" provide additional cooling and serve as a captive running direction indicator.

Advantages for the user

- Extremely low vibration

- Extremely clean cutting edges

- An extremely low amount of friction, resulting in low heat generation

- Extremely quiet-running

- Extremely accurate

- An extremely low amount of undercut

- Extremely quick

- Diamond cutting discs become blunt at excessively high rotation speeds and wear too rapidly at insufficient peripheral surface speeds

- If ease of cutting is lost (indicated by heavy sparking), resharpen the disc in abrasive material, e.g. sandstone, with several cuts

- Separate larger workpiece cross-sections into several sections (swing cut)

- Work without applying pressure — the weight of the machine is sufficient. Increased pressure causes increased wear.

- Diamond cutting discs are designed for straight cutting. Cutting curves deforms the blade and results in core cracks and segment tear-offs — risk of injury!

- Despite the level of safety offered by the tool, always wear protective goggles and clothing while working

- Observe the information on the label (max. rotation speed), the restrictions of use and the safety instructions

- The direction arrow on the disc must match the machine's direction of rotation

- Must not be used for lateral grinding

- Use the appropriate protective hood

- Clamping must be performed only by a trained specialist (do not use force, use clean clamping flanges of the same size, perform a test run)

- If grinding tools are clamped or used incorrectly or are damaged, they represent a danger and may cause serious injury

Datasheets(X)

For dry and wet cutting. Specially designed for particularly hard materials that tend to cause other discs to "burn".

Frequent applications

Old concrete/concrete, exposed aggregate concrete, reinforced concrete, concrete tiles/pan tiles, concrete bricks/pipes, sand-lime brick, granite/marble, marble, stoneware. Cast-iron pipes, clinker bricks, glazed pan tiles, hard Poroton, mortar/plaster etc.

Versatility (points system) | 3 of 4 points |

Service life (points system) | 4 of 4 points |

Cutting speed (point system) | 4 of 4 points |

Cut quality (point system) | 4 of 4 points |

Diameter (Ø) | 230 mm |

Drill hole | 22.23 mm |

Number of segments x segment height | 12 x 12 mm |

Number of segments x segment height 2 | 3 x 15 mm |

Segment thickness | 2.6 mm |

Segment connection | Laser |

Max. rotation speed | 6600 rpm |

Max. circumferential speed | 80 m/s |

| Properties |

| Versatility |

| Service life |

| Cutting speed |

| Cutting quality |